The Mitsubishi Inverter Manual provides essential guidelines for installing, operating, and maintaining Mitsubishi Electric inverters. It ensures safe and optimal performance, covering key functions, parameters, and safety protocols. Available in print and digital formats, the manual is a crucial resource for users to maximize efficiency and comply with operational standards.

1.1 Overview of the Mitsubishi Inverter Series

The Mitsubishi Inverter Series offers high-performance, energy-efficient solutions for motor control applications. Models like FR-D700, FR-E700, and FR-A800 provide flexible and reliable operation across various industries. Designed for versatility, these inverters support advanced control methods, including vector control and sensorless vector control, ensuring precise motor management. They are compatible with peripheral devices and communication networks, making them ideal for integrated systems.

1.2 Importance of the Instruction Manual

The Mitsubishi Inverter Instruction Manual is crucial for safe and efficient operation. It provides detailed installation, wiring, and maintenance guidelines, ensuring users can optimize performance. The manual also outlines safety precautions, parameter settings, and troubleshooting tips, making it an indispensable resource for both novice and experienced users to avoid potential risks and maintain compliance with operational standards.

1.3 Safety Precautions and General Warnings

The Mitsubishi Inverter Manual emphasizes critical safety measures to prevent accidents. It highlights risks like halogen-based material exposure, which can damage equipment. Proper handling and installation are stressed to avoid fire or electric shock. Users must adhere to guidelines for EMI reduction and ensure compliance with EMC standards. Ignoring these precautions can lead to system failure or personal injury, underscoring the importance of following instructions to ensure safe and reliable operation.

Installation and Wiring Guidelines

Proper installation and wiring are crucial for safe and efficient inverter operation. Ensure correct tools and materials are used, and follow detailed procedures to prevent damage and ensure compliance with safety standards and manufacturer guidelines.

2.1 Necessary Tools and Materials

Ensure you have the correct tools and materials for installation, such as screwdrivers, pliers, and wrenches. Use appropriate MCCBs, USB connectors, and communication cables. Refer to the manual for specific requirements and ensure all components are Mitsubishi-compatible to guarantee safe and efficient installation.

2.2 Step-by-Step Wiring Instructions

Begin by disconnecting the power supply before starting. Connect the AC input to the inverter’s terminals, ensuring correct phase alignment. Wire the motor output carefully, matching the inverter’s output terminals to the motor’s input. Use RS-485 communication terminals for external control. Refer to the manual for specific wiring diagrams and model-specific instructions, such as for the FR-A800 series. Always follow safety guidelines to avoid electrical hazards.

2.3 Peripheral Devices and Compatibility

Ensure compatibility by connecting approved peripheral devices like the FR-PU07 parameter unit and FR-DU08 operation panel. Use RS-485 communication for external control and Modbus-RTU for industrial networks. USB connectors enable configuration via software tools. Verify device compatibility with your inverter model, such as the FR-A800 series, to ensure seamless integration and optimal performance. Always refer to the manual for specific pairing recommendations;

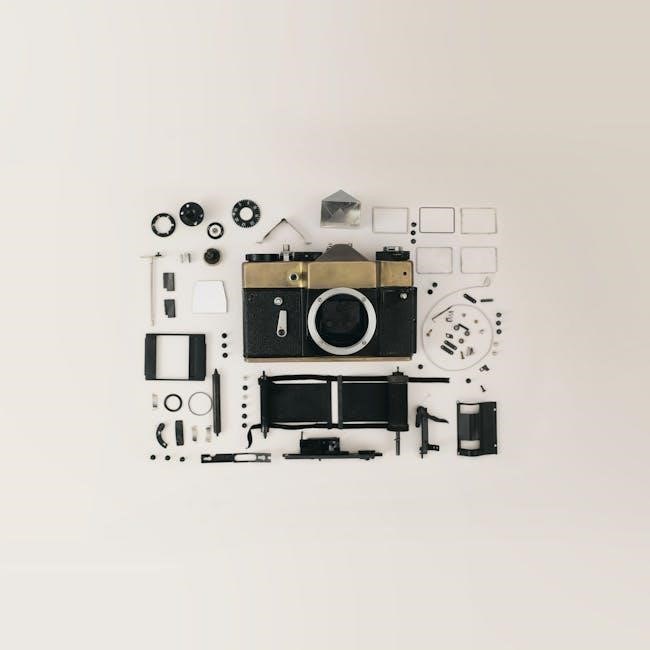

Understanding Inverter Components

The Mitsubishi inverter comprises key hardware components such as the power module, control unit, and cooling system. The operation panel and parameter unit enable monitoring and adjustments, ensuring efficient operation.

3.1 Key Hardware Components

The Mitsubishi inverter features essential hardware components, including the power module, control unit, and cooling system. These elements ensure efficient power conversion and stable operation. The power module handles high-current flow, while the control unit manages operational parameters. The cooling system maintains optimal temperatures, preventing overheating. These components are designed for durability and performance, ensuring reliable operation in various industrial applications. Proper understanding of these parts is crucial for effective setup and maintenance.

3.2 Operation Panel and Parameter Unit

The operation panel and parameter unit are integral for controlling and configuring the Mitsubishi inverter. The operation panel provides a user-friendly interface for setting frequencies and monitoring operations. The parameter unit allows advanced adjustments, enabling customization of settings to meet specific application needs. Together, these components ensure precise control and optimal performance, making them essential for efficient inverter operation and maintenance. Proper use of these tools enhances productivity and system reliability.

Operation Parameters and Configuration

This section covers the configuration and customization of Mitsubishi inverters, optimizing motor performance through advanced settings and control methods for enhanced operational efficiency and productivity.

4.1 Basic Operation Parameters

The basic operation parameters of Mitsubishi inverters are essential for controlling motor speed and torque. These include frequency, voltage, and motor speed settings, ensuring smooth operation. Correct configuration of these parameters is critical for optimizing performance and preventing damage. They are typically set during installation and are detailed in the manual to guide users through the initial setup process effectively.

4.2 Advanced Parameter Settings

The advanced parameter settings in Mitsubishi inverters enable precise control and customization for specific applications. These include vector control for high-precision motor management, torque boost for increased productivity, and energy-saving modes to minimize power consumption. Configuring these settings correctly ensures optimal performance, efficiency, and reliability in various industrial environments and load conditions. Always refer to the manual for detailed configuration guidelines.

4.3 Control Methods and Modes

Mitsubishi inverters offer multiple control methods and modes to suit various applications. These include V/F control for simple motor operation, vector control for high-precision applications, and sensorless vector control for advanced motor management. Additional modes like energy-saving and multi-speed operations enhance flexibility. The manual provides detailed instructions for selecting and configuring these modes to optimize performance and efficiency in industrial environments.

Safety Instructions and Precautions

Adhering to safety guidelines is crucial to prevent hazards. Avoid exposure to halogen materials, ensure proper grounding, and handle high-voltage components with caution. Follow manual instructions to prevent damage or injury.

5.1 Handling Halogen-Based Materials

Halogen-based materials, such as fluorine, chlorine, and bromine, can damage Mitsubishi inverters. If exposed, these substances may infiltrate components, leading to irreversible damage. Proper handling and storage are essential. Avoid using materials containing halogens near inverters. Follow disposal guidelines to prevent environmental contamination. Immediate cleaning and maintenance are required if exposure occurs to ensure optimal performance and prevent system failure.

5.2 Power Supply Harmonics and EMI

Mitsubishi inverters may generate power supply harmonics, potentially affecting overall system performance. These harmonics can cause overheating, reduced component lifespan, and inefficiency. Proper filtering and grounding are essential to minimize harmonic distortion. Additionally, electromagnetic interference (EMI) from inverters can disrupt nearby electronic devices. Mitsubishi recommends using EMI-compliant filters and shielding cables to mitigate these issues, ensuring compliance with electromagnetic compatibility standards for reliable operation.

Maintenance and Inspection

Regular maintenance ensures optimal inverter performance. Inspect components, clean as needed, and replace worn parts promptly. Follow Mitsubishi’s guidelines for detailed checklists and procedures.

6.1 Daily and Periodic Inspection Checklists

Regular inspections ensure the inverter operates efficiently and safely. Daily checks include verifying power indicators, ensuring proper cooling, and inspecting for dust or debris. Periodic inspections involve checking terminal connections, cleaning filters, and verifying parameter settings. Refer to the manual for detailed checklists and schedules. Neglecting these steps may lead to reduced performance or unexpected failures, emphasizing the importance of adherence to Mitsubishi’s guidelines.

6.2 Cleaning and Replacement of Parts

Regular cleaning prevents dust buildup, ensuring proper heat dissipation and component longevity. Use compressed air or soft brushes for the heat sink and fan. Replace parts like capacitors or fans when worn. Always use Mitsubishi-approved replacements. Power down the inverter before maintenance to avoid accidents. Follow manual guidelines for safe procedures, preventing damage and ensuring optimal performance and reliability over time.

Troubleshooting Common Issues

This section addresses common inverter issues, such as fault codes, power supply problems, and communication errors. It provides step-by-step solutions for quick resolution and optimal performance.

7.1 Identifying Fault Codes

Mitsubishi inverters display fault codes to indicate specific issues. These codes, such as E1, E2, or ALARM messages, help diagnose problems like overcurrent, overheating, or communication errors. The manual provides a detailed list of codes, their meanings, and troubleshooting steps. Users should refer to the manual to identify the cause of a fault and follow recommended actions, such as checking connections or resetting parameters, to restore normal operation and prevent further damage.

7.2 Resolving Power Supply and Communication Issues

Power supply issues may stem from voltage fluctuations or harmonic interference, while communication problems often arise from improper RS-485 wiring or incorrect parameter settings. Users should check power quality, ensure proper grounding, and verify communication settings. Consulting the manual for fault codes and performing diagnostic checks can help resolve these issues efficiently, ensuring reliable inverter operation and preventing downtime.

Additional Resources and Downloads

Mitsubishi Electric offers additional resources and downloads through MELFANS Web, including PDF manuals, software tools, and technical notes. Users can access detailed guides for models like FR-D700 and FR-E700, ensuring comprehensive support for inverter setup and troubleshooting.

8.1 Accessing Mitsubishi Electric FA Network (MELFANS Web)

MELFANS Web is Mitsubishi Electric’s dedicated FA network service, providing easy access to inverter-related resources. Users can download PDF manuals, software tools, and technical notes. The platform supports various models, including FR-D700 and FR-E700, ensuring comprehensive assistance for installation, configuration, and troubleshooting. Visit MELFANS Web to explore and download necessary materials efficiently.

8.2 Downloading PDF Manuals and Software Tools

Mitsubishi Electric offers convenient access to PDF manuals and software tools through the MELFANS Web platform. Users can download detailed guides for models like FR-D700 and FR-E700, along with setup manuals and technical notes. These resources provide comprehensive support for installation, configuration, and troubleshooting, ensuring optimal performance of Mitsubishi inverters. Visit MELFANS Web to access these materials.

The Mitsubishi Inverter Manual serves as a comprehensive guide for safe and efficient operation of Mitsubishi Electric inverters. By following the instructions, users can ensure optimal performance, troubleshoot issues, and maintain their systems effectively. Proper installation, configuration, and regular maintenance are key to maximizing the lifespan and functionality of Mitsubishi inverters. Always refer to the manual for detailed guidance and support.

No Responses